NxG Carrier Inverter Ductable AC Features:

- Enables Energy Saving and Precision Temperature Control

- In-Built Safety: Carrier AC ductable prevents damage to the rectification bridge and capacitator.

- Comprehensive PCB protection is provided in these Carrier AC ductable

- Surge-protected.

In-Built Electrical Safety in Drive:

- Phase Reversal

- Phase Sequencing

- Issue Undervote

- Phase Loss

- Overvote

- Overcurrent

No Deration Up To 43 Degree C.:

Uncompromised Capacity Deliverance Despite High Summer Temperatures.

Electronic expansion valve:

- Precise refrigerant volume control.

- Stepper Motor for precise feedback mechanism.

BMS Compatibility:

- Integrated control via RS485 communication port.

- Enables efficient operation.

Optimum Performance:

- Provides enhanced comfort and precise temperature control.

- High energy savings with variable ambient temperatures and loads.

- Lower inrush of current.

- Prevents over-cycling of motor compressors.

- Controls power consumption during peak loads.

Intelligent airflow management:

- Comfortable Room Ambience

- A multi-speed motor fan maintains airflow.

- Eliminates discomfort from heat pocket formations.

Improved system design:

- Carrier AC ductable has installation flexibility.

- Longer piping up to 50 meters is possible because of the improved system design.

- Minimal deration compared to a fixed-speed system.

Electromagnetic interference (EMI) filter RE:

- Carrier Ductable AC Unit has Electromagnetic Interference filters resulting in robust operation and reliability.

- Suppresses electromagnetic interference from nearby equipment.

- Immunizes unit to service disturbances.

Green Field Project benefits using Carrier AC ductable units:

- Energy Cost Savings:

- 40% annual energy cost reduction.

- 11% lower lifecycle cost.

- 35% lower installed cost.

- Yearly payback.

Retrofit Projects:

- Minimal System Change Requirements

- No need to alter the ducting system in this Carrier ductable AC.

- Only equipment and piping need modification.

- 50% Annual Energy Cost Savings

- Payback period: 2 years

Carrier AC ductable has various unit features:

- Wide screen LED multifunction controller

- Wireless remote control

- Corded remote with the error logging feature

Enhanced reliability devices:

Accumulator:

- Converts remaining liquid refrigerant into gas.

- Protects the compressor from permanent damage.

Service Valves:

- Factory-fitted refrigerator service valve

- Easy restoration post-service operation.

Reduced footprints:

- 11HP NxG ODU Footprint Reduction

- It results in 30% lower footprint as compared to 8.5 TR Fixed Speed Ductable Outdoor Unit.

- As compared to 11 Ton (TR) conventional fixed-speed Ductable Outdoor unit, the NxG Inverter Ductable Outdoor unit of capacity 14 HP results in 20% lower footprint.

Installation Ease of Carrier Ductable AC:

- Compact filter width (25mm)

- Easy DIY filter replacement

- Compatible with greenfield and retrofit projects

The filter lifecycle - Runs good Before and After

- RoHS compliant (1200 hours of operation)

- Before Wash 800 hours

- After Wash 400 hours

Advanced Digital Display for MERV 11 Filter (PM 2.5 100 ug/m3 AQI GOOD)

- For real-time air quality updates, the state-of-the-art sensors are provided.

- For easy identification of air quality, 4 color displays are provided.

- Includes digital indicators for real-time monitoring.

- Includes brightness control for adjustable display level.

- Comes with a 5-meter wire for flexible installation.

MERV 11 FILTER: Comes with a State-of-the-Art Sensor:

- Laser Sensor Increases accuracy and sensitivity.

- And that actually allows for automatic calibration in order to avoid manual re-calibration.

- Compact, lightweight design for easy installation.

Advanced Inverter Technology:

- Based on the cooling load, the Advanced inverter technology modulates / adjusts the speed of the compressor.

- Maintains consistent temperature by modulating power, reducing energy consumption by 30–50%.

Powerful and uniform air distribution:

- Robust ducting system for efficient airflow distribution.

- Eliminates hot spots for uniform cooling.

- That is ideal for offices, large rooms, and commercial spaces.

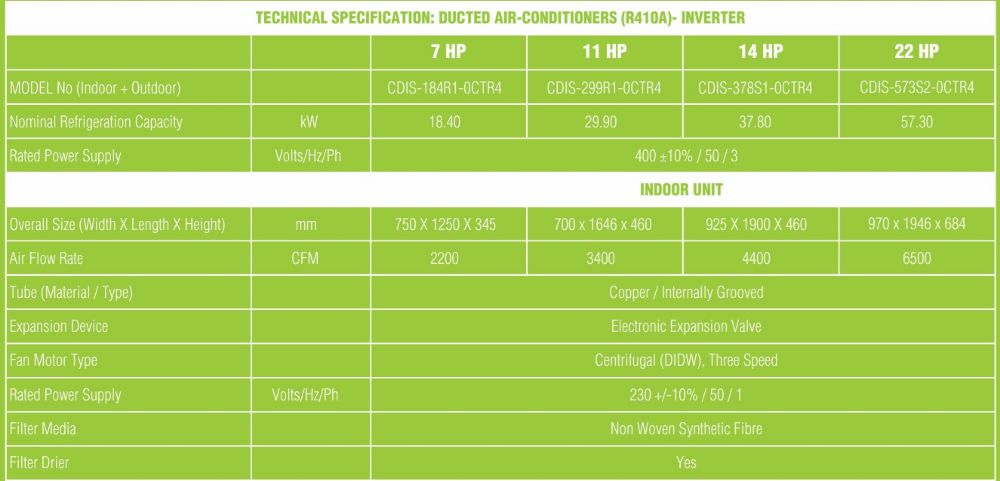

Specifications Of Carrier Inverter Ductable AC:

Model Numbers:

Indoor + Outdoor:

- CDIS-184R1-0CTR4 (7 HP or 5.5 TR),

- CDIS-299R1-0CTR4 (11 HP or 8.75 TR),

- CDIS-378S1-0CTR4 (14 HP or 11 TR),

- CDIS-573S2-0CTR4 (22 HP or 17 TR)

Nominal Refrigeration Capacity:

- CDIS-184R1-0CTR4: 18.40 kW

- CDIS-299R1-0CTR4: 29.90 kW

- CDIS-378S1-0CTR4: 37.80 kW

- CDIS-573S2-0CTR4: 57.30 kW

Rated Power Supply (Volts/Hz/Ph):

- 400 ± 10% Volts / 50 Hertz / 3 Phase

Indoor Unit Specifications:

- Overall Size of the indoor unit (Width - Length - Height in mm):

- CDIS-184R1-0CTR4: 750 x 1250 x 345

- CDIS-299R1-0CTR4: 700 x 1646 x 460

- CDIS-378S1-0CTR4: 925 x 1900 x 460

- CDIS-573S2-0CTR4: 970 x 1946 x 684

- Air Flow Rate (CFM):

- CDIS-184R1-0CTR4: 2200 CFM

- CDIS-299R1-0CTR4: 3400 CFM

- CDIS-378S1-0CTR4: 4400 CFM

- CDIS-573S2-0CTR4: 6500 CFM

- Tube Material/Type: Copper / Internally Grooved

- Expansion Device: Electronic Expansion Valve

- Kind of Fan Motor: Three speed and Centrifugal (DIDW)

- Rated Power Supply (Volts/Hz/Ph) **: 230 ± 10% / 50 / 1

- Filter Media: Non-Woven Synthetic Fiber

- Filter Drier: Yes

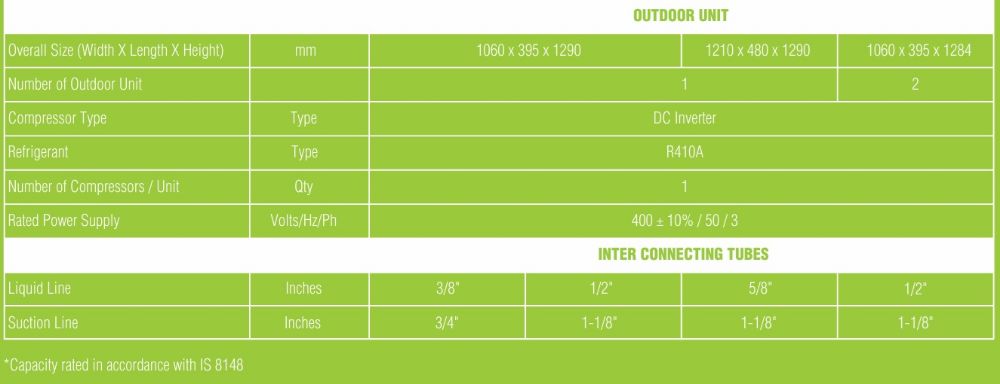

Outdoor Unit Specifications:

- Overall Size of the Outdoor Unit (Width - Length - Height in mm):

- CDIS-184R1-0CTR4: 1060 x 395 x 1290

- CDIS-299R1-0CTR4: 1060 x 395 x 1290

- CDIS-378S1-0CTR4: 1210 x 480 x 1290

- CDIS-573S2-0CTR4: 1060 x 395 x 1284 (2 Outdoors)

- Compressor Type: DC Inverter

- Refrigerant Type: R410A

- Number of Compressors per Unit**: 1

- Rated Power Supply (Volts/Hz/Ph) **: 400 ± 10% / 50 / 3

Interconnecting Tubes:

- Liquid Line (Inches):

- CDIS-184R1-0CTR4: 3/8"

- CDIS-299R1-0CTR4: 1/2"

- CDIS-378S1-0CTR4: 5/8"

- CDIS-573S2-0CTR4: 1/2"

- Suction Line (Inches):

- CDIS-184R1-0CTR4: 3/4"

- CDIS-299R1-0CTR4: 1-1/8"

- CDIS-378S1-0CTR4: 1-1/8"

- CDIS-573S2-0CTR4: 1-1/8"

How to Install Carrier Inverter Ductable AC:

Carrier AC Ductable installation process:

Planning and Preparation of Ductable AC Carrier:

- Identify a central location for the indoor unit in the inverter ductable AC installation process.

- Make sure to assess the structural support of the ceiling / wall structure.

Installation of Ductable AC Carrier:

- Install hanging rods or brackets securely into the ceiling or wall.

- Secure the indoor unit with threaded rods or hanging rods and ascertain that it is level and firmly in place without any vibrations.

- Connect the ductwork to the indoor unit’s supply and return air openings.

Installation of the Outdoor Unit:

- Select an appropriate location on a flat, stable surface.

- Mount the outdoor unit on a concrete pad or sturdy mounting bracket.

Connecting Refrigerant Lines and Electrical Wiring:

- Run the refrigerant lines from the indoor to outdoor unit.

- Connect the power supply and control wiring between the indoor and outdoor units.

Testing and Final Adjustments of Ductable AC Carrier:

- Vacuum and charge the system.

- Test the system and adjust the airflow and settings as needed.

Final Inspection and Handover:

- Inspect the installation for any issues in the Carrier inverter ductable AC.

- Provide user instructions on the operation of the Carrier Inverter Ductable AC.